Project Objective

A newly launched project, of the Canadian Coalition for Green Health Care (Coalition), Reducing Health Care-Related PPE and Medical Single Use Plastic Waste Through Circular Economy Principles, will demonstrate that hospital-generated PPE and mSUP materials can be successfully managed by applying the principles of a circular economy: reduce, reuse and recycle as much as possible before the materials are disposed of. This project will explore and identify reuse and reduction opportunities for PPE and selected mSUPs, which will complement and enable resource conservation.

This project helps address several Government of Canada initiatives such as the following:

- In November 2018, the Canadian Council of Ministers of the Environment adopted Canada’s Zero Plastic Waste Strategy to reduce the environmental impact of plastics and promote a circular economy [1].

- Canada supports the premise that the world needs a sustainable recovery from the COVID-19 pandemic and will be joining the Finnish and the Netherlands to host three high-level events to address the important role circularity plays in the economies of the future as well as in the fight against climate change and the nature crisis [2].

- To reduce the environmental impact of PPE in Canada, the Government of Canada is supporting the development of solutions that will lead to more sustainable PPE, including reusability, alternative materials, improved recyclability, novel recycling technologies and compostability [3].

- The Canadian Net-Zero Emissions Accountability Act delivers on the Government of Canada’s commitment to legislate Canada’s target of net-zero greenhouse gas emissions by 2050. The Act will establish a legally binding process to set five-year national emissions-reduction targets for 2030, 2035, 2040, and 2045, as well as develop credible, science-based emissions-reduction plans to achieve each target. [4].

- The Pan-Canadian Framework on Clean Growth and Climate Change is Canada's plan – developed with the provinces and territories and in consultation with Indigenous peoples – to meet Canada's emissions reduction targets, grow the economy, and build resilience to a changing climate. [5]

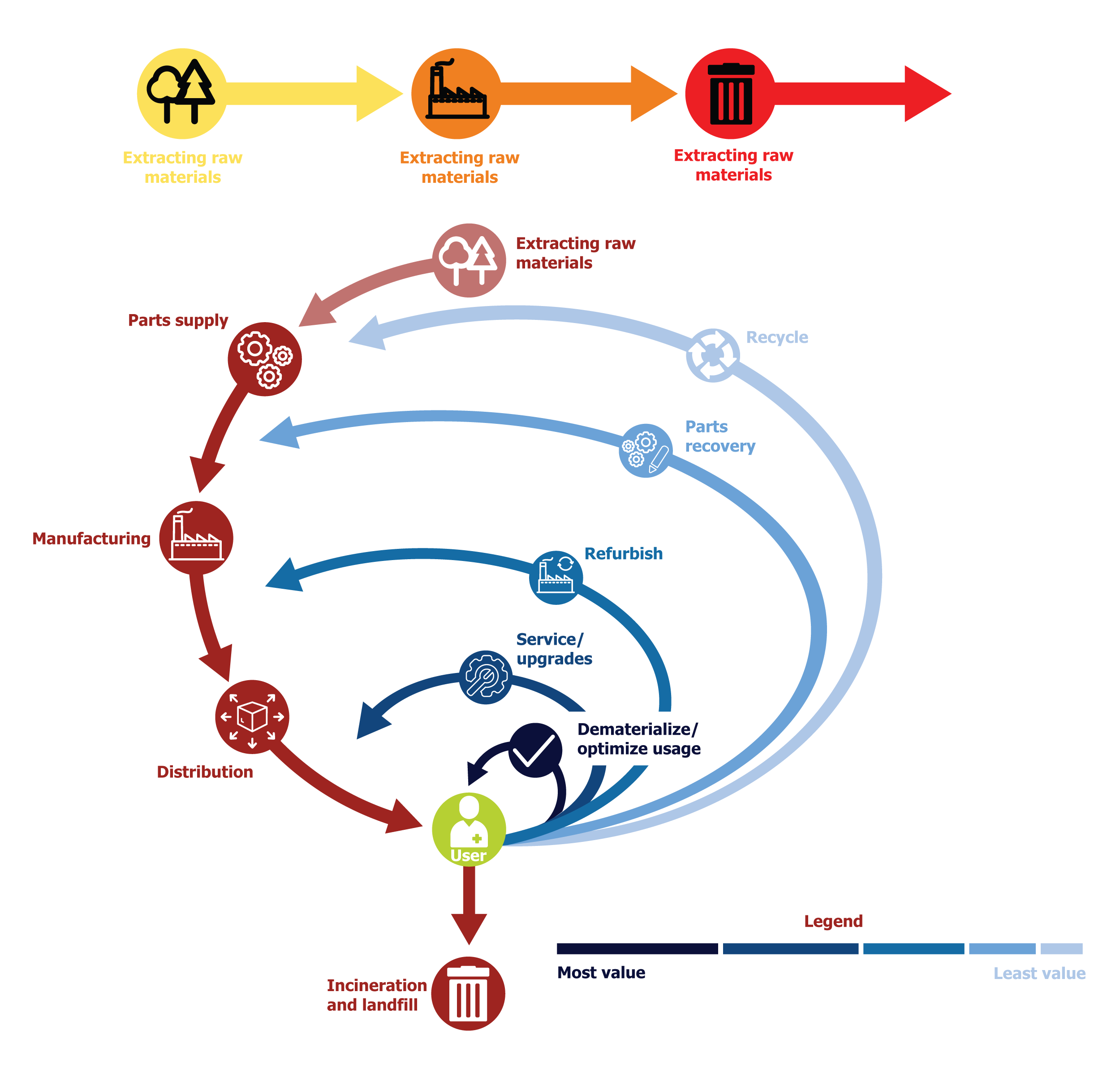

Linear Economy vs. Circular Economy

This is an interactive graphic! Click on the icons below to learn more about each element.

PPE Circular Economy

A linear economy holds no sustainable value for health care. Health care’s participation in a circular economy (CE), however, would provide a major opportunity to yield direct benefits to the sustainability and efficiency of the delivery of health care services and indirect benefits from reducing harmful environmental impacts of hospital-generated waste (WHO, 2018). [6]

Waste

This is the last component of the linear economy, and indicates the end of the product lifecycle. At this point, products are discarded where they stagnate in landfills and damage the surrounding natural environment.

Extracting raw materials

Raw material extraction is a very initial stage in the circular economy when raw materials enter the system from outside. However, the goal of the circular economy is to phase out this step such that the materials in the system are continually circulated without the need for new raw materials from outside the circular economy.

Parts supply

The extracted raw materials are processed to make different parts that go into products. This is an intermediary step that has input from the raw material extraction step as well as the recycling step.

Manufacturing

Manufacturing is a key component of the circular economy since the PPE and mSUP products that are produced need to be built in such a way that they can be reused, refurbished, reprocessed and/or recycled further down in the system.

Distribution

The circular economy encourages the development of a resilient and strategic supply chain, that can aid in manufacturing durable and innovative PPE and mSUP products.

User

Users' consumption of PPE and mSUPs drives production and distribution. Therefore, a reduction or optimisation in consumption of new products is of paramount importance to drive the re-usage of PPE and mSUPs.

Incineration and landfill

The incineration and landfill step is the absolute last resort component of the circular economy, and is carried out only with particular materials and components that cannot remain in the system.

Dematerialize/optimize usage

Optimizing usage of PPE and mSUPs can play a key role in prolonging the product lifecycle. While the users do play a key role in ensuring this happens, the products themselves must be reusable in the first place. Listed below are some aspects to consider:

- Designing and manufacturing products that can be reused more than one time through cleaning and sterilization techniques

- Substituting cleaning agents which can be generated onsite (aqueous ozone), decreasing the need to continually buy new products

- Ultra-violate disinfection versus toxic chemical usage

- Establishment of online asset sharing platforms between hospitals or health authorities

- Create local supply chains

- Design equipment to be easily reparable

Service/upgrades

The service step emphasises the need for regular service and maintenance of the products to prolong product life.

Refurbish

Refurbishing PPE is key to prolonging the lifecycle, thereby optimizing product use and enabling product circularity. Listed below are some key points to consider:

- Optimize products through a redesign, enabling product circularity

- Use high-quality materials to enable reuse before requiring refurbishing

- Utilize modular design to allow for parts swapping and refurbishing

Recycling

Recycling is the next step in the circular economy after parts recovery. It is important to note that recycling is not the "go-to" solution in a circular economy as the focus is more on prolonging product lifecycle through reuse, repair and reprocessing. Listed below are some of the things to keep in mind before recycling PPE:

- Ensure highly efficient sorting and recycling systems are in place

- Only recycle products at the end of their life cycle

- Only recycle products that cannot be reused due to outstanding circumstances

Parts recovery

The parts recovery step deals with extracting parts and components from the products, which can then add to the stream of parts supply, to be used in manufacturing new products.

Take

The first step in the linear economy involves the process of extracting raw materials required for the manufacture of products. This is typically done on an ongoing basis at an increasing rate due to the lack of used materials in the system and ever-increasing demand for various products.

Make

This component focuses primarily on efficient and cost-effective manufacturing of products, which can then be distributed for consumption. All materials used are typically harvested from natural reserves or manufactured from similar materials. There is no re-usage of previously used materials here.

Adapted from "CleanMed Europe, Collaborating to Achieve Healthcare Circularity," by Health Care Without Harm Europe and Philips, 2020. Copyright 2020 by Philips. Adapted with permission.

Idealized circular economy system with a future focus on reusable personal protective equipment. Copyright 2022 by Canadian Coalition for Green Health Care.

Project Components

- Engaging health sector and stakeholder experts on PPE and medical SUPs reduction and reuse

- Determining PPE and medical SUPs purchased in hospitals and opportunities for reduction, and reuse

- Designing the scenarios to reduce and reuse PPE

- Knowledge generation and translation deliverables will be provided in English and French and will be designed to enable the hospital sector across Canada to reduce and reuse PPE/SUPs following the completion of this project.

Resources

Read the CCGHC's literature review - A circular economy model for hospital generated PPE ad medical single use plastic waste: Demonstrating opportunities for reduction and reuse.

Article for Canadian Healthcare Facilities - COVID-19 and PPE Waste: A catalyst for a reusable personal protective equipment health system

Checklist for health care workers - Circular Economy Best Practices Checklist: For PPE use in health care facilities

Infographic - Benefits of a reusable PPE system in health care

Webinars & Events

Webinar 1: What to do with hospital PPE and medical single-use plastic waste?

Tuesday, May 11, 2021

9 am PDT/ 12 pm EDT/ 1 pm ADT

Presentation 1: Reducing Hospital-Related PPE and Medical Single-Use Plastic Waste Through Circular Economy Practices

Presented to the Federal-Provincial/Territorial Sub Working Group on Reducing PPE Waste

July 20, 2021

Presentation: The Changing Landscape of PPE in Canada

Presented to CleanMed Europe in 2021, by Kady Cowan and Ozora Amin

Towards a Safe, Secure and Sustainable Reusable PPE System in Canadian Health Care

The Canadian Coalition for Green Health Care demonstrates how transitioning to a reusable PPE system can result in environmental benefits, cost savings, and stability for health care facilities without sacrificing the safety of patients and health care workers.

Presented May 26th, 2022 at 9am PT/12m ET/1pm AT

Watch the webinar en français.

Case Studies Map

Video Project

The Way Forward is Reusable: Demonstrating Canadian opportunities for safe, secure and sustainable PPE

The Coalition hopes this video will break down misconceptions regarding reusable PPE, incite discussion on sustainability and waste reduction in health care, and inspire health care workers to advocate for reusable PPE systems in their facilities.

This video could not be possible without the support and collaboration of health care workers across Canada. Thank you for your participation.

Community Engagement

Community engagement is a crucial part of this project. We have a dedicated Google Groups forum for project communication and regular community engagement.

See the instructions below to join the PPE-mSUP Reducing, Reusing, Recycling Project group:

- If you have a Google account, click HERE to request access to the Google Group

- If you do not have a Google account, email ppe-msup-project@googlegroups.com to request access to the Google group

CCGHC Team and Associates

Neil Ritchie

Executive Lead

Linda Varangu

Project Lead

Kent Waddington

Communications Advisor

Kady Cowan

Project Technical Lead

Ozora Amin

Project Coordinator

Mia Sarrazin

Bilingual Environmental Health Care Coordinator

Autumn Sypus

Marketing and Outreach Coordinator

Steering Committee

Kady Cowan

Project Technical Lead

Canadian Coalition for Green Health Care

Linda Varangu

Project Advisor

Canadian Coalition for Green Health Care

Fiona Miller

Professor of Health Policy

University of Toronto

Marianne Dawson

Sustainability Consultant - Recycling and Waste Reduction

British Columbia GreenCare

Patricia Trbovich

Badeau Family Research Chair in Patient Safety and Quality Improvement, North York General Hospital

Associate Professor, University of Toronto

Ozora Amin

Project Coordinator

Canadian Coalition for Green Health Care

Edward Rubinstein

Director, Environmental Compliance, Energy & Sustainability

University Health Network

Lesley Anne Hirst

Director,

IPAC Lead Ontario Health

Project Partners

University Health Network (UHN) | University of Toronto | BC GreenCare

External Evaluator

Cameron D. Norman

Principal & President

Cense Ltd.

Project Funder

References:

[1] Zero plastic waste: Canada’s actions. March 24, 2021.

[2] Government of Canada launches new COVID-19-related challenges to help reduce environmental impact of PPE in Canada. Oct 12, 2020.

[3] Finland, Canada and the Netherlands join forces to advance the circular economy as key to a sustainable recovery. June 25, 2020.

[4] Canadian Net-Zero Emissions Accountability Act.

[5] Pan-Canadian Framework on Clean Growth and Climate Change.

[6] World Health Organization. (2018). Circle economy and health: Opportunities and risks.